In a business, various concepts & formulae are used to optimize the entire process, and this article is about three important terms that can be very helpful to your organization. We are talking about Takt Time, Cycle Time, and Lead Time. These are the terms used in multiple industries to optimize the process and deliver better results to their clients. We will also understand the difference between the Takt Time, Cycle Time, and Lead Time in the article, so hang in till the end.

What is Takt Time?

Takt is basically a German word for “baton” that a conductor uses in the orchestra to manage the tempo of music. In simple words, Takt means a beat or a pulse in the music. In terms of business, Takt Time means the rate at which the product needs to be manufactured to satisfy the customer demand.

How To Calculate Takt Time (Ideal)?

Suppose you have 500 minutes per day for manufacturing, and the customer demand is 500 units per day, you have 1 minute to produce a unit. That’s your Takt Time.

Takt time can be calculated using this simple formula below:

Takt Time = Available Time For Production/Number of Units Required

How To Calculate Takt Time (Real)?

As we all know, ideal calculations are way different than the real situations. So, let’s try and calculate Takt Time using some real conditions.

Total Hours of Working = 8 Hours

Total Minutes of Working = 480 Minutes

Lunch Break = 30 Minutes

Tea Breaks = 2* 15 Minutes = 30 Minutes

Total Productive Minutes = Total Minutes Of Working – (Lunch Break + Tea Breaks)

= 480 – (30+30)

= 420 Minutes

Total Requirements from client = 250 Units/day

Takt time = Total Productive Minutes/Total Requirement

= 420250

= 1.68

What Are The Benefits Of Calculating Takt Time?

There are some important benefits of calculating Takt Time, let’s have a glance:

- You can find the exact time to produce one unit.

- Avoid the situation of overproduction.

- You can decide a precise guideline for the delivery.

- Can also be used to determine the organizational efficiency.

- You can manage overtime calculations.

- Production rate can be streamlined.

What is Cycle Time?

As the name suggests, Cycle Time is the time taken to produce one unit from the start to the end. Cycle time gives you the idea of how much time will it take to complete the demand, according to the current rate.

How To Calculate Cycle Time?

Let’s take an example:

Suppose, your team is working 50 hours a week, producing a total of 100 units. Here’s the formula to calculate the Cycle Time:

Cycle time = No. Of Productive Hours/Total Units Produced

= 50/100

= 0.5 Hour

If your Takt Time is more than 0.5 hour, you must do something about it. But if your Takt Time is below 0.5 hour, everything looks smooth!

Benefits of Calculating Cycle Time

- Gives an actual idea of the production rate.

- Gives data to make changes in the production rate to satisfy the demand.

- Deciding the actual time of delivery.

Takt Time Vs Cycle Time

Takt time and Cycle Time has different uses. In simple terms, Takt Time is to find the maximum time one can spend on one unit before getting the order. Cycle time simple means, how much time it is taken to complete one unit.

You can simply use Takt Time as the reference to complete the delivery on time. And when you find Cycle Time, your efforts should be about matching it with the Takt Time.

What is Lead Time?

Lead time has different use compared to Takt Time and Cycle Time. Lead time consists of the entire journey of one unit from the scratch to the end. In simple words, Lead time is the total time taken for a unit from getting an order to receiving payment. So, Lead Time is not only about the production but it is about the entire process of your organization.

How To Calculate Lead Time?

To calculate Lead Time, we must take an example to clearly understand the concept.

Let’s assume, the client gives the order on January 1st. You receive the order on January 2nd. After receiving the order, your team starts the process of manufacturing units on January 3rd. Entire cycle to manufacture the order takes 10 days, so January 13th is the day you complete the manufacturing. Now, the delivery takes about 2 days, so we have reached January 15th. After checking your entire order, the client takes 4 days to make the payment, hence January 19th.

To sum up, the Lead Time for this example will be 19 days. An interesting thing about Lead Time is, no matter how less time you take in manufacturing, you have to cut down other processing time to shorten the Lead Time.

Cycle Time Vs Lead Time

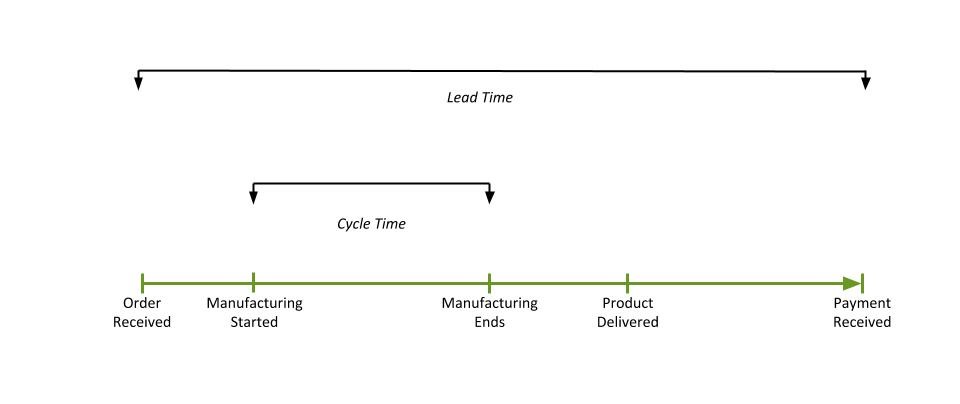

Here is an image that completely explains the difference between Cycle Time and Lead Time. Let’s have a look:

The cycle suggests the manufacturing process of your company, where Lead Time shows the entire process of your company including the Cycle Time. In terms of maths, Cycle Time is the subset of Lead Time.

CT ⊂ LT

Which Business Approach Is Best For Takt Time, Cycle Time, and Lead Time?

Now that we know the importance of all three – Takt Time, Cycle Time, and Lead Time, it’s important to understand which approach you should choose in business.

When it comes to production or manufacturing, your effort should lie in making Cycle Time as close as Takt Time. This approach would help in delivering the order on time.

Talking about the Lead Time, your efforts should lie in making it as short as possible. If you optimize the Cycle Time, then Lead Time will be automatically optimized. Other tasks like planning, packaging, or delivering are included in Lead Time. You can optimize the entire process to shorten the Lead Time.

Share your views about the other uses of Takt Time, Cycle Time and Lead Time in the comment section below.

Cheers!

Check out MinterApp for the best Time Tracking & Invoicing Solutions